Using jetting tubes and a water pump wellpoint dewatering is a fast and cost effective way to decrease water levels.

Well point dewatering system cost.

Because the system is typically installed in an outdoor environment extreme weather conditions during certain times of the year can decrease production rates for the system s installation team thereby increasing labor costs.

Complete dewatering was established in 1923 and began the manufacturing and development of ground water control systems to predrain and stabilize wet soils.

Capable of handling flow up to 5 200 gallons per minute these pumps are ideal for dewatering systems in pervious soils.

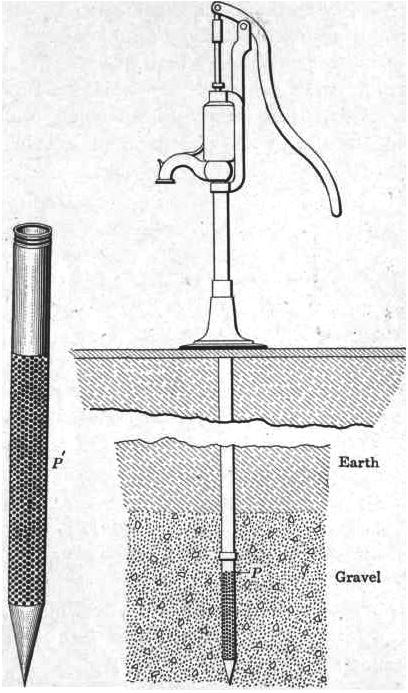

The threaded octagon shoulder prevents turning while driving and forms a hole large enough to allow clearance for pipe couplings.

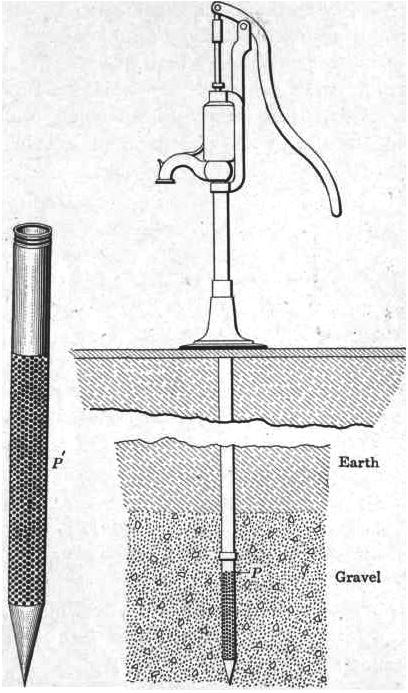

Pre drill and hand spearing with water jetting system.

Well point assemblies made up of a well point screen riser pipe and swing joint with tuning are generally installed by jetting.

These wellpoints are connected to a main pipe and are pumped out of the ground with a high efficiency water pump.

Dewatering pumps wellpoints cdpw specializes in the layout installation and operation of construction dewatering systems bypass pumping pump and equipment sales.

Herc rentals wellpoint pumps are available in 6 8 and 12 inch models.

These pumps are designed to handle large volumes of water and air.

Well point systems a well point system consists of a number of well points spaced along a trench or around an excavation site all connected to a common header which is attached to one or more well point pumps.

Hand spearing with water jetting system.

Bryan dairy road construction dewatering preliminary layout cost estimate dewatering near side and far side of streets no.

Sand tubing prodder.

There are few drawbacks.

Below methods used to install wellpoint dewatering system.

The simplicity of the system makes it possible to scale dewatering to just about any level necessary for the construction project.

Unit unit cost cost cost basis 1 6 header w well points 3 bryan dairy north no 1 a b 200 lf 5 25 1 050 00 croy dewatering.

Our wellpoint dewatering system uses small diameter shallow wells that are evenly spaced.

Plastic well point is engineered to provide an ideal combination of easy driving effective sand control corrosion resistance and strength.

Cdpw has been the market leader in the industry by providing.

Wellpoints are 50mm tubes with slots near the bottom that are inserted into the ground from which water is drawn by vacuum generated with a dewatering pump.

The method is well suited when close spacing is required.

Wellpoint systems can be expanded to thousands of wellpoints that use multiple pumping stations.

Plastic well this 1 1 4 in.